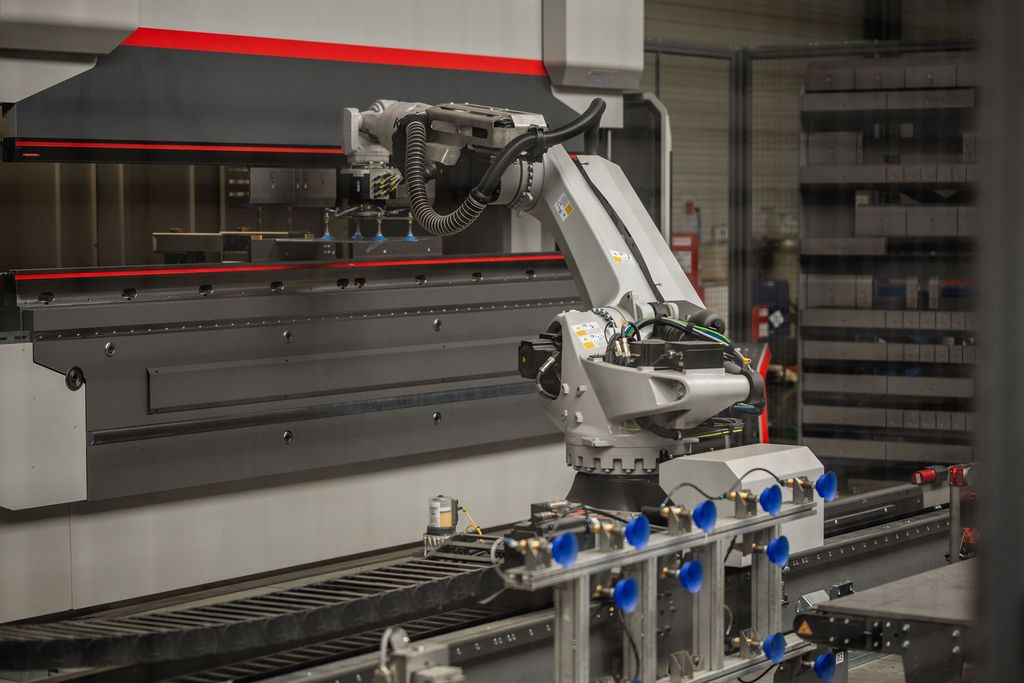

Our machinery

An eclectic range of state-of-the-art machines

Organised to optimise the production process as much as possible, our machines are chosen for their high technical potential, but also for the way they complement each other. Thanks to them, we can now handle the entire metalworking process.